In the fast-paced world of automotive technology, flexible multilayer PCBs are becoming a cornerstone for innovation and efficiency. As a leading manufacturer, Hongmy specializes in producing flexible multilayer PCBs that cater to the unique demands of modern vehicles. Here's how these cutting-edge components are revolutionizing the automotive industry.

1. Lightweight and Compact Designs

With the growing demand for electric vehicles (EVs) and smart cars, space and weight have become critical factors in automotive design. Flexible multilayer PCBs are inherently lightweight and adaptable, allowing manufacturers to fit complex circuitry into smaller spaces without compromising performance. This innovation reduces overall vehicle weight, which directly improves fuel efficiency and battery life.

2. Enhanced Reliability in Harsh Environments

Automobiles are exposed to extreme conditions, including temperature fluctuations, vibrations, and moisture. Flexible multilayer PCBs are designed to endure these harsh environments. Their robust construction ensures long-term reliability, reducing the risk of failure in critical systems such as engine management, braking, and safety controls.

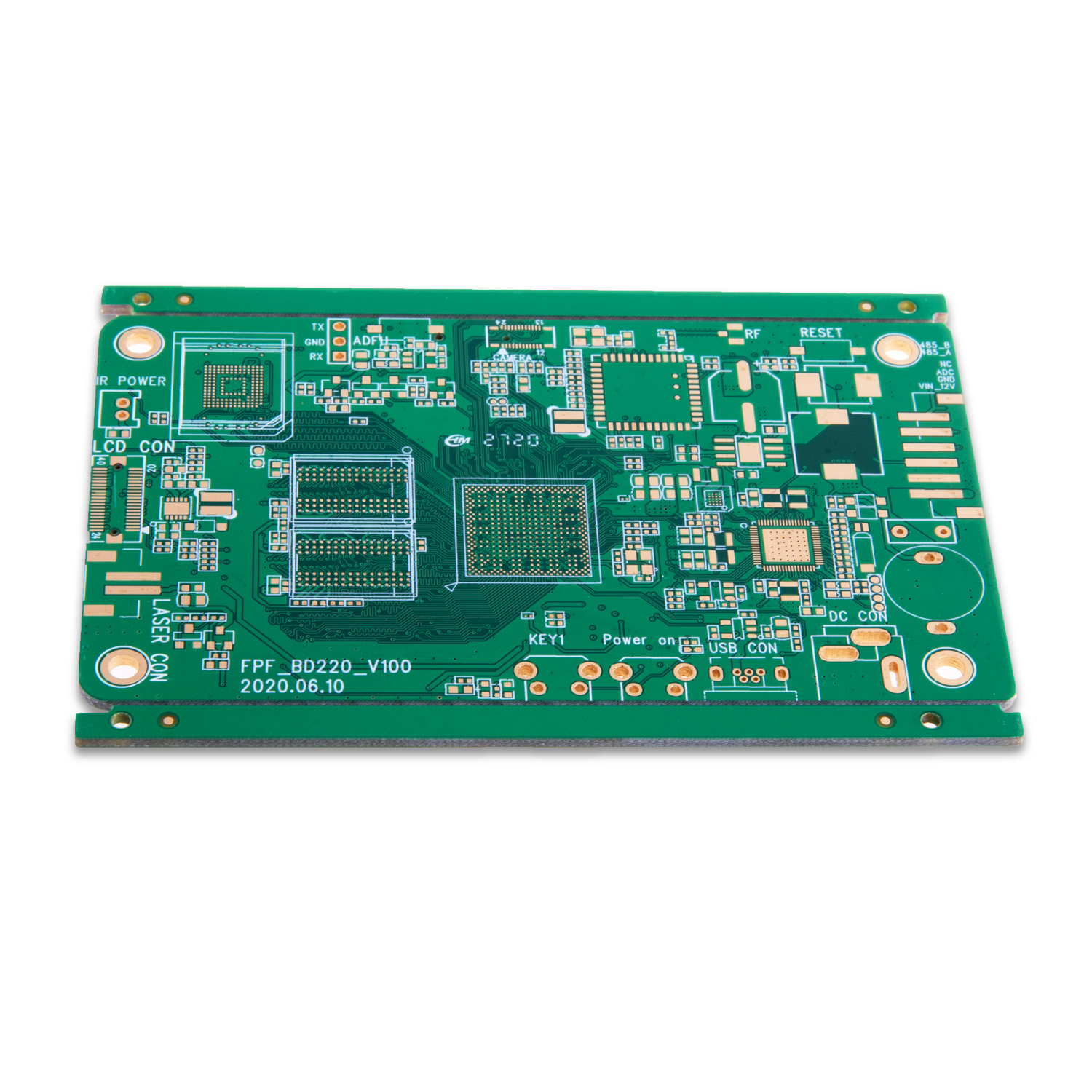

3. Supporting Advanced Driver-Assistance Systems (ADAS)

The integration of ADAS features, like collision detection, lane assistance, and autonomous driving, requires high-performance PCBs with complex designs. Flexible multilayer PCBs offer the connectivity and signal integrity needed to support these advanced systems, ensuring seamless communication between sensors, processors, and actuators.

4. Powering Electric Vehicles

The rise of EVs has created a demand for more efficient energy management solutions. Flexible multilayer PCBs are pivotal in battery management systems (BMS) and charging systems, providing precise control and monitoring to maximize energy efficiency and safety.

5. Cost-Effective and Scalable Solutions

Automotive manufacturers require scalable solutions to meet diverse production needs. Flexible multilayer PCBs are not only cost-effective but also versatile, accommodating both low-volume prototypes and high-volume production. This scalability ensures manufacturers can innovate quickly without incurring prohibitive costs.

6. Applications in Infotainment Systems

Modern vehicles are equipped with advanced infotainment systems that demand high-speed data transmission and compact designs. Flexible multilayer PCBs support high-frequency signals and fit seamlessly into the limited spaces of dashboards, enabling superior audio, video, and navigation capabilities.

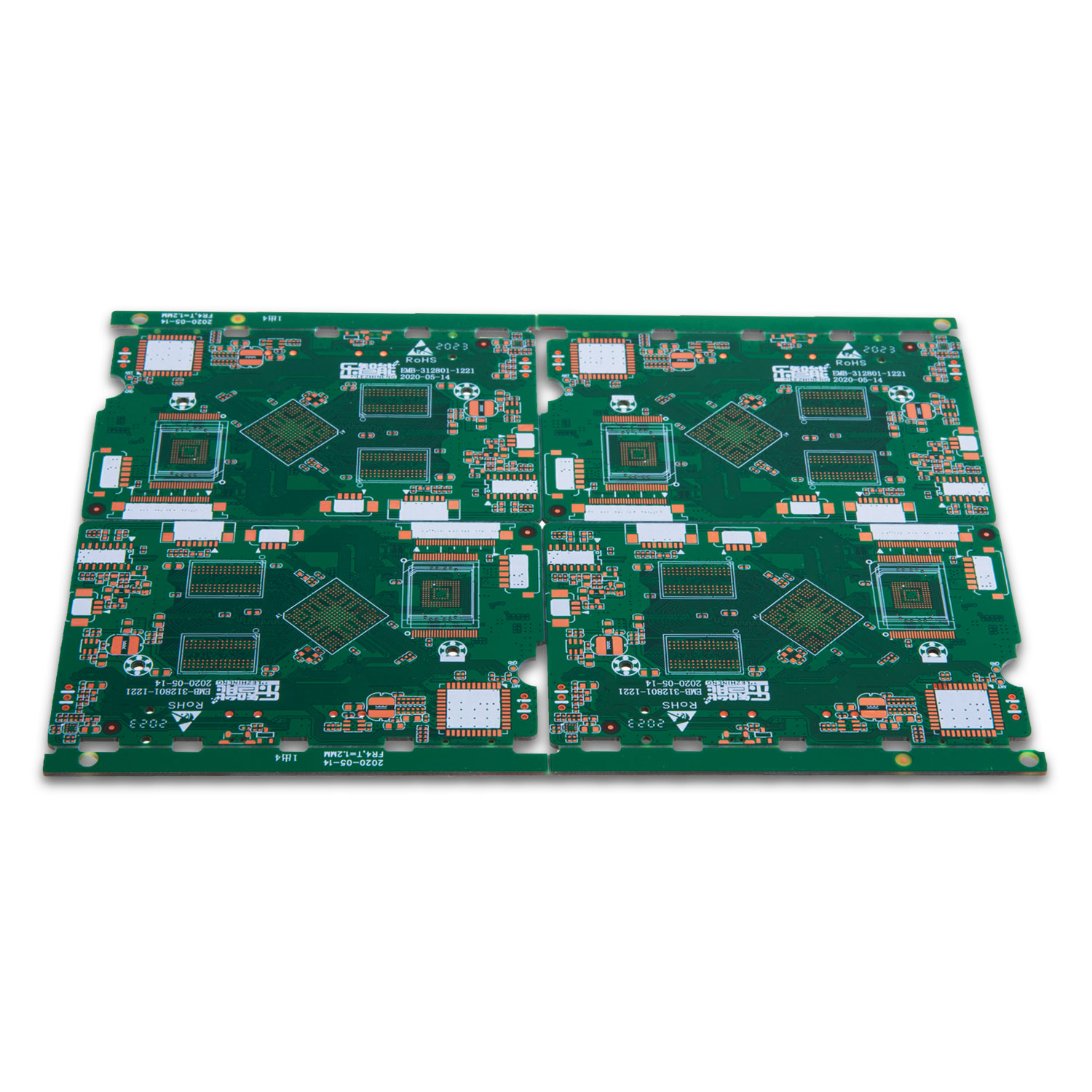

Why Choose Hongmy for Flexible Multilayer PCBs?

As a trusted name in the PCB manufacturing industry, Hongmy delivers high-quality flexible multilayer PCBs tailored to the automotive sector. Our state-of-the-art facilities and experienced engineers ensure precision and performance in every product.

- Customizable Designs: We cater to specific requirements for automotive applications.

- Advanced Materials: Our PCBs are made from durable and high-performance materials.

- Compliance: All products meet stringent automotive standards, including ISO/TS 16949.

Conclusion

Flexible multilayer PCBs are not just transforming the automotive industry; they are shaping the future of mobility. From enhancing vehicle safety to enabling smarter technologies, these PCBs play an essential role in modern automotive design.

For high-quality flexible multilayer PCBs, trust Hongmy to deliver innovative solutions that drive your projects forward. Visit us at Hongmy Circuits to learn more about our products and services.