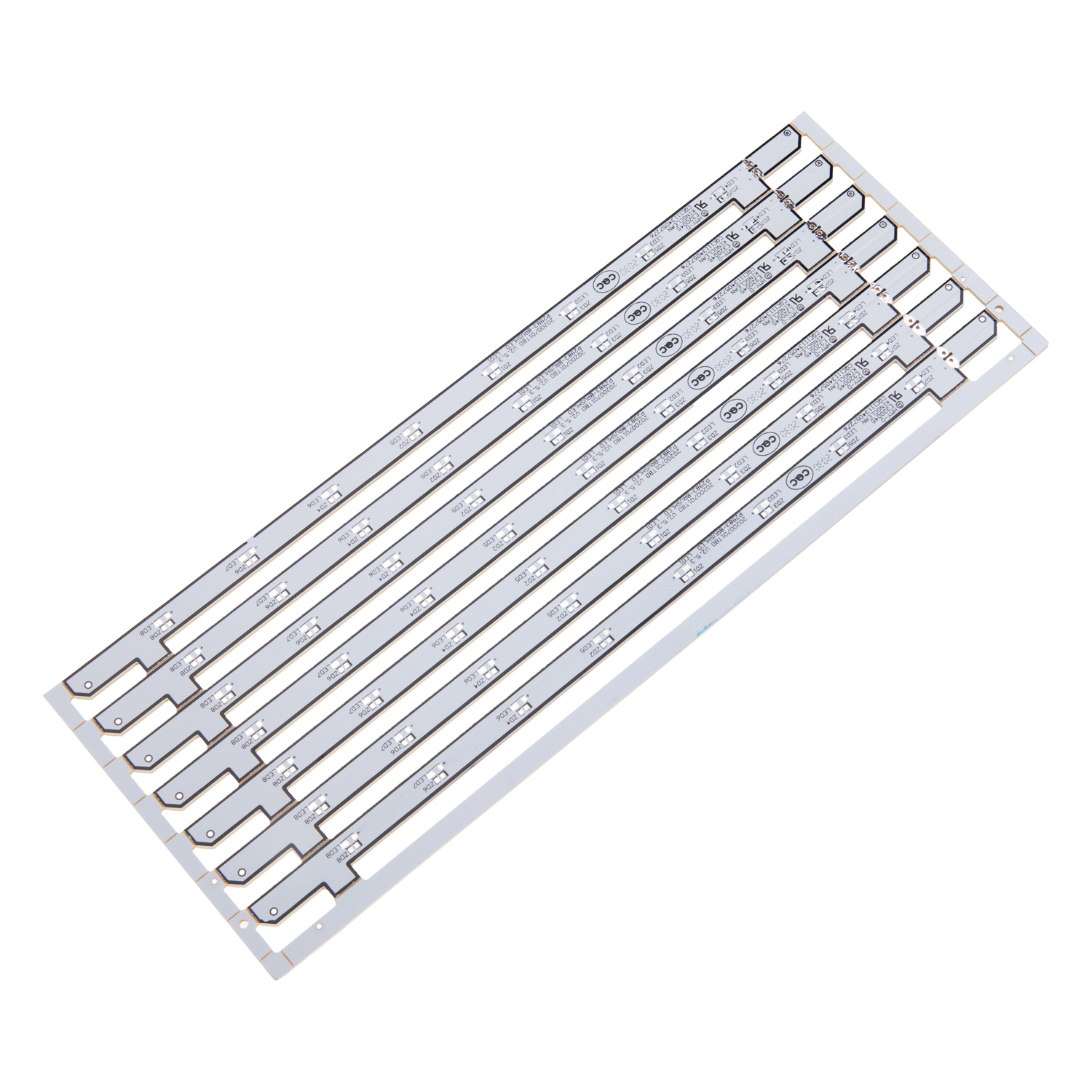

Metal core PCBs (MCPCBs) are increasingly popular in LED lighting applications due to their superior heat dissipation, durability, and efficiency. As LED lights generate significant heat during operation, standard PCBs struggle to manage these thermal demands effectively. Metal core PCBs, specifically designed with a metal layer (usually aluminum or copper), provide enhanced thermal conductivity, making them ideal for dissipating heat away from LED components, extending their lifespan, and ensuring stable performance.

Why Metal Core PCBs for LED Lighting?

1.Efficient Heat Dissipation

One of the primary challenges in LED lighting is managing heat. Metal core PCBs are designed to address this issue by transferring heat away from the LED components. The metal core layer efficiently conducts heat, preventing overheating and ensuring that LEDs operate at optimal temperatures. This is crucial for preventing damage and extending the LED’s life cycle.

2.Durability and Longevity

LEDs are known for their longevity, but their durability can be compromised by excess heat. Metal core PCBs enhance LED lifespan by offering better thermal stability. This makes them ideal for high-power LED applications, including industrial lighting, automotive lighting, and outdoor fixtures. The robust design of metal core PCBs ensures they can withstand tough environments while maintaining performance.

3.Improved Energy Efficiency

By regulating the temperature more efficiently, metal core PCBs help LEDs run more efficiently. Lower operating temperatures allow LEDs to use energy more effectively, which not only reduces power consumption but also improves the overall performance of the lighting system. For applications that prioritize energy efficiency, such as street lighting or household LED bulbs, metal core PCBs are the perfect solution.

4.Application Flexibility

Metal core PCBs can be customized to suit various LED applications. Whether it’s for commercial, residential, or industrial LED lighting, they offer flexibility in terms of thickness, layer count, and core materials. This adaptability ensures that you can achieve the best possible design for your specific lighting needs.

5.Thermal Management for High-Power LEDs

High-power LEDs, commonly used in automotive headlights, street lights, and floodlights, generate substantial heat. Metal core PCBs are particularly useful for these applications, as they prevent thermal overload and enhance the light's overall reliability and performance.

Why Choose Hongmy for Metal Core PCBs?

As a trusted manufacturer of metal core PCBs, Hongmy specializes in providing high-quality PCB solutions tailored to LED lighting applications. Our MCPCBs are built to the highest standards, ensuring optimal heat dissipation and reliability for your LED systems. Whether you need custom designs or large-volume orders, Hongmy is equipped to deliver efficient solutions for your lighting projects.

Visit our website Hongmy Circuits to learn more about our metal core PCB offerings for LED applications and other advanced PCB technologies.

In conclusion, metal core PCBs are indeed suitable for LED lighting due to their superior heat dissipation, durability, and ability to improve overall energy efficiency. For manufacturers and designers aiming for high-performance, long-lasting LED lighting systems, metal core PCBs are the go-to solution.