Unleash the Full Potential of Your Electronic Devices with Heavy Copper PCBs

Heavy copper pcbs (Printed Circuit Boards) have revolutionized the electronics industry, offering a robust and reliable solution for high-power applications. By incorporating thick copper layers into the PCB design, these specialized boards amplify durability and performance, enabling electronic devices to operate at their full potential.

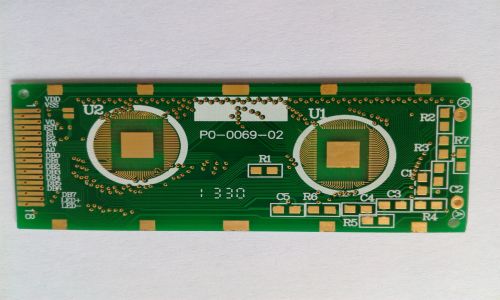

What are Heavy Copper PCBs?

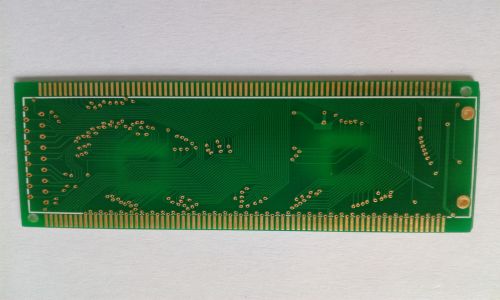

Heavy Copper PCBs, also known as Power PCBs, are designed to withstand high levels of current and heat. These boards have copper layers that are significantly thicker than standard PCBs, typically ranging from 3 ounces to 20 ounces or even more. The increased copper thickness allows for better heat dissipation and reduces the risk of voltage drop, making Heavy Copper PCBs ideal for power electronics and applications with demanding thermal requirements.

Advantages of Heavy Copper PCBs

1. Enhanced Durability: The thick copper layers in Heavy Copper PCBs provide increased structural integrity, making them more resistant to mechanical and thermal stress. This durability ensures a longer lifespan and improved reliability for electronic devices.

2. Improved Thermal Management: Heavy Copper PCBs excel at dissipating heat due to their enhanced copper thickness. This feature effectively reduces the operating temperature of electronic components, thereby enhancing overall performance and preventing premature device failures.

3. Higher Current Carrying Capacity: With their thicker copper layers, Heavy Copper PCBs offer higher current carrying capacity, allowing for the smooth transmission of high-power signals. This capability is crucial for power electronics and applications with heavy current requirements, such as power supplies, motor controllers, and renewable energy systems.

4. Reduced Voltage Drop: The low electrical resistance provided by the thick copper layers minimizes voltage drop, ensuring consistent power delivery across the PCB. This is particularly important for high-power applications, as voltage drop can negatively impact device performance and efficiency.

5. Increased Design Flexibility: Heavy Copper PCBs offer greater design flexibility compared to standard PCBs. The thick copper layers allow for the creation of complex and compact circuit designs, enabling engineers to optimize the layout and functionality of electronic devices.

Applications of Heavy Copper PCBs

Heavy Copper PCBs find extensive use in various industries and applications:

- Automotive: Electric vehicles, battery management systems, power distribution units

- Aerospace: Avionics, satellite systems, power converters

- Industrial: Power supplies, motor drives, solar inverters

- Telecommunication: Base stations, network infrastructure

- Medical: Imaging devices, diagnostic equipment, implantable devices

Conclusion

Heavy Copper PCBs provide a game-changing solution for demanding electronic applications that require high durability, thermal management, and current carrying capacity. With their enhanced features, these specialized PCBs unleash the full potential of electronic devices, ensuring optimal performance and reliability. Whether in automotive, aerospace, industrial, telecommunication, or medical fields, Heavy Copper PCBs enable engineers to develop cutting-edge products that meet the evolving needs of the modern world.