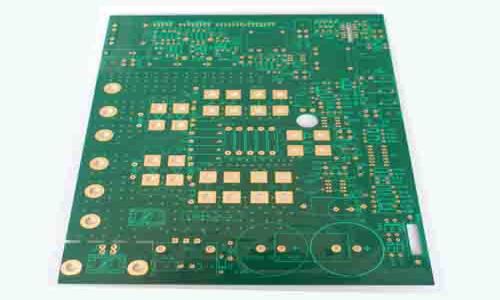

Electronics Revolution: The Power of Heavy Copper PCBs

In the fast-paced world of electronics, innovative technologies drive progress. One such advancement that is revolutionizing the industry is the utilization of heavy copper printed circuit boards (PCBs). These high-power PCBs are transforming the way electronics are designed and manufactured, enabling unprecedented capabilities and superior performance. Let's delve into the advantages of Heavy Copper PCBs and discover how they empower the electronics industry.

1. Enhanced Power Handling

Heavy Copper PCBs are specifically engineered to handle high current and power applications. With significantly thicker copper traces and planes, these PCBs offer lower electrical resistance, ensuring efficient power distribution and minimizing voltage drops. This enhanced power handling capability makes them ideal for power electronics, automotive applications, renewable energy systems, and more.

2. Increased Thermal Management

Heat dissipation is a critical factor in electronics, as excessive temperatures can lead to device failure. Heavy Copper PCBs excel in thermal management due to their thicker copper layers, which act as efficient heat sinks. The increased copper volume helps dissipate heat more effectively, preventing overheating and enhancing the overall reliability and lifespan of electronic devices.

3. Improved Durability and Mechanical Strength

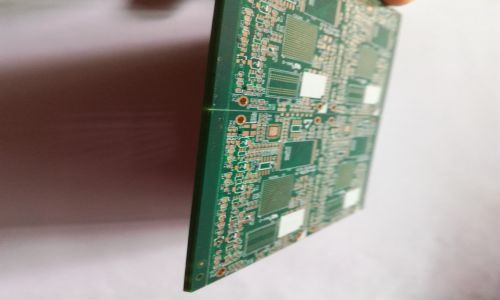

The additional copper thickness in Heavy Copper PCBs enhances the board's mechanical strength and durability, enabling it to withstand harsh operating conditions. These PCBs offer higher resistance to thermal stress, vibration, and mechanical strain, making them suitable for demanding applications that require long-term reliability, such as aerospace, military, and industrial sectors.

4. Design Flexibility and Current Carrying Capacity

The use of Heavy Copper PCBs allows for greater design flexibility, as the increased copper thickness offers higher current-carrying capacity compared to standard PCBs. This feature enables engineers to optimize circuit designs, reduce board size, and enhance overall system performance. High-density interconnects and complex multilayer designs can be achieved, accommodating demanding electronic applications that require miniaturization.

5. Cost-Effective Solution

Although Heavy Copper PCBs require additional processing and materials, they offer a cost-effective solution in the long run. The improved power handling and thermal management capabilities eliminate the need for additional components, such as heat sinks or cooling systems, reducing overall system costs. Additionally, the enhanced durability and reliability of Heavy Copper PCBs result in reduced maintenance and replacement costs, making them a wise investment for various industries.

Conclusion

Heavy Copper PCBs are empowering the electronics industry with their exceptional power handling, thermal management, durability, design flexibility, and cost-effectiveness. These high-performance PCBs have transformed the way electronic devices are designed and manufactured, enabling the development of advanced technologies across numerous sectors. As technology continues to evolve, Heavy Copper PCBs will play a crucial role in enabling the next generation of innovative and powerful electronic devices.