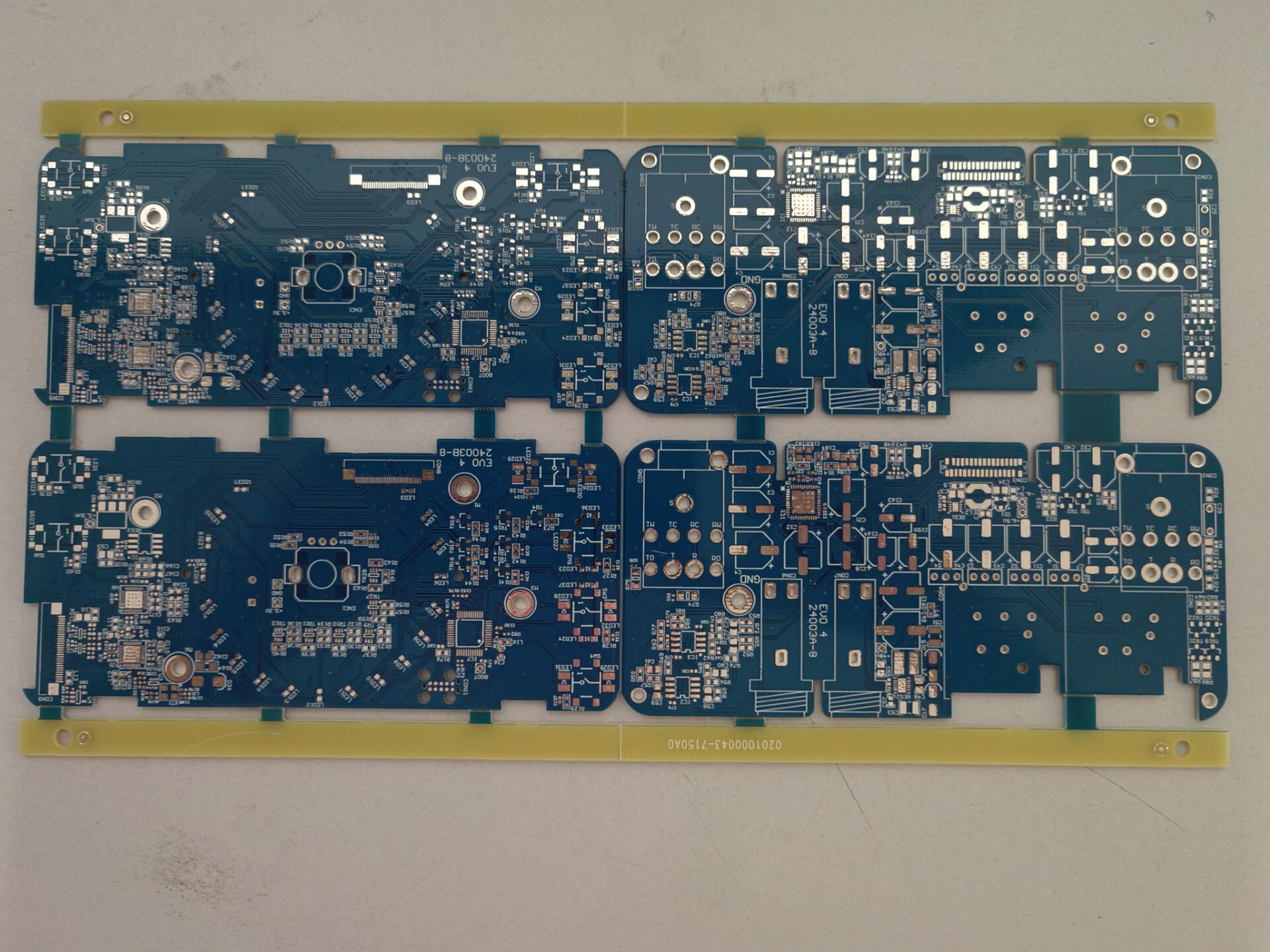

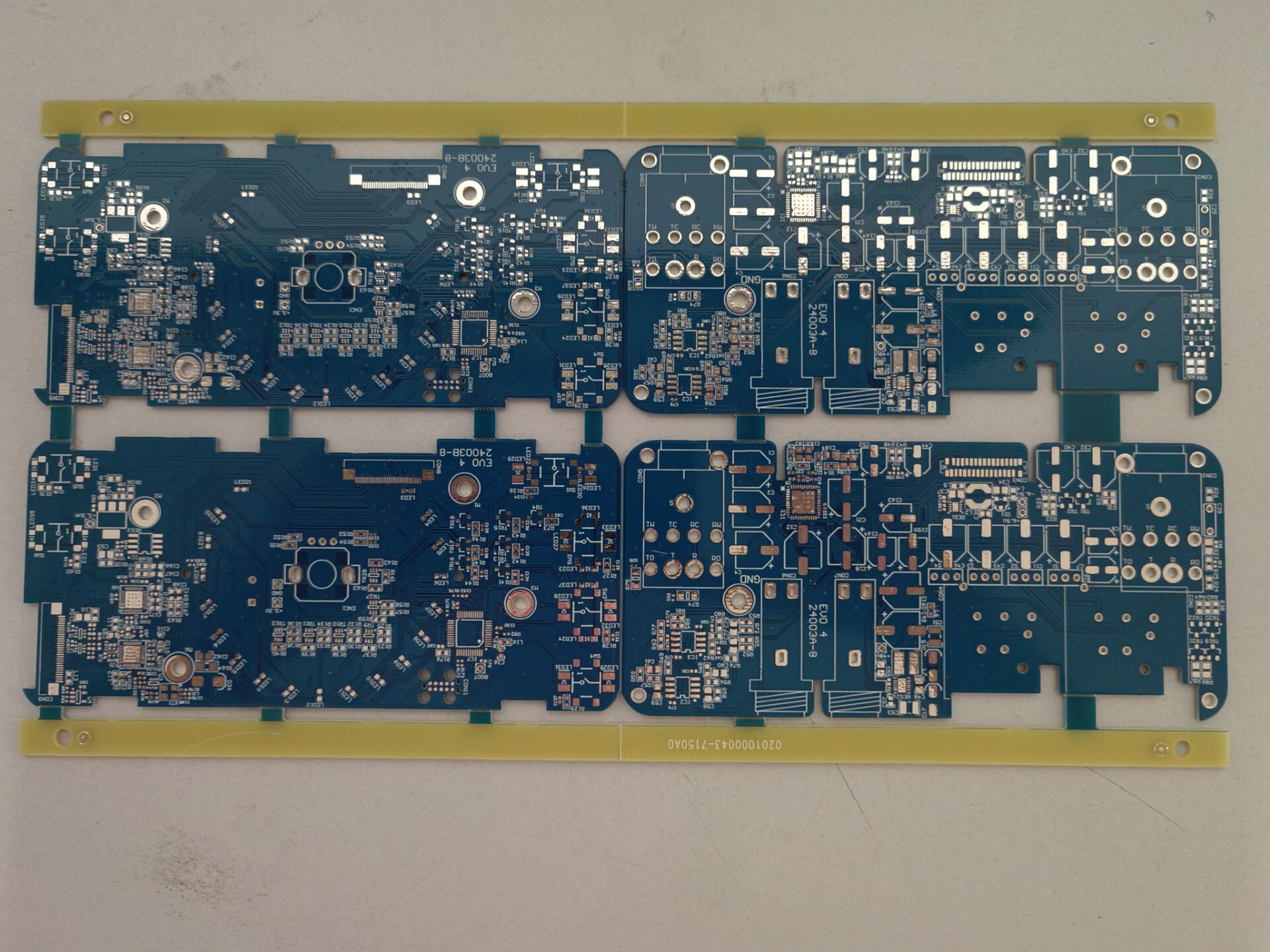

Introduction to Immersion Gold Surface Circuit Boards

Immersion Gold (ENIG) surface finish is a popular technology in the Printed Circuit Board (PCB) industry, known for providing excellent surface quality, long shelf life, and superior solderability. It involves applying a thin layer of gold over a nickel layer on the PCB surface, offering excellent electrical conductivity and resistance to oxidation.

In this blog, we’ll explore what immersion gold surface circuit boards are, how they work, their advantages, and where they are commonly used.

What Is an Immersion Gold Surface Circuit Board?

An immersion gold surface circuit board features a coating of gold over a nickel layer, providing a smooth, flat surface for soldering components. The nickel serves as a barrier to prevent copper from diffusing into the gold, ensuring durability and reliability. This finishing process, known as Electroless Nickel Immersion Gold (ENIG), is widely used due to its excellent solderability and ability to accommodate fine-pitch components.

How Immersion Gold PCB Process Works

The ENIG process involves two steps:

1.Nickel Plating: A layer of nickel is deposited on the copper surface of the PCB.

2.Gold Plating: A thin gold layer is then deposited over the nickel, preventing oxidation.

The gold layer is very thin, typically between 2-5 microinches, and acts as a protective barrier that helps ensure the longevity and reliability of the board during soldering.

Advantages of Immersion Gold Surface Boards

High Durability: The nickel-gold combination offers robust mechanical strength, making it ideal for complex designs.

Excellent Solderability: Immersion gold provides a smooth and flat surface, perfect for precise soldering of components.

Oxidation Resistance: Gold prevents oxidation, ensuring longer shelf life and better performance in harsh environments.

Better for Fine-Pitch Components: Ideal for boards with small pitch components, where other surface finishes may fail.

Enhanced Electrical Conductivity: Gold’s conductivity ensures stable electrical performance, reducing signal loss and improving circuit integrity.

Common Applications

Due to its high durability and reliability, immersion gold surface PCBs are commonly used in:

Aerospace and Defense: The high performance and reliability of ENIG make it suitable for mission-critical systems.

Telecommunication Devices: Immersion gold’s high conductivity and fine-pitch component compatibility are essential for modern communication devices.

Medical Equipment: Precision and reliability make ENIG PCBs indispensable in medical electronics.

Automotive Industry: Used in car sensors and control systems for reliable, long-lasting performance.

How to Choose the Right PCB Manufacturer for Immersion Gold Boards

When selecting a PCB manufacturer for immersion gold circuit boards, it's important to consider:

Experience with ENIG Finishes: Look for a manufacturer with proven expertise in producing ENIG surface boards.

Custom Design Capabilities: Manufacturers like Hongmy Circuits offer custom solutions tailored to your specific needs.

Quality Control: Choose a manufacturer with stringent quality checks to ensure reliability.

Conclusion

Immersion gold surface circuit boards provide an excellent combination of durability, conductivity, and solderability, making them an ideal choice for various high-performance applications. If you’re looking for a reliable supplier, Hongmy Circuits offers high-quality custom PCBs with ENIG surface finishes, ensuring precision and long-term reliability.

Contact Hongmy Circuits today for expert solutions tailored to your project needs.