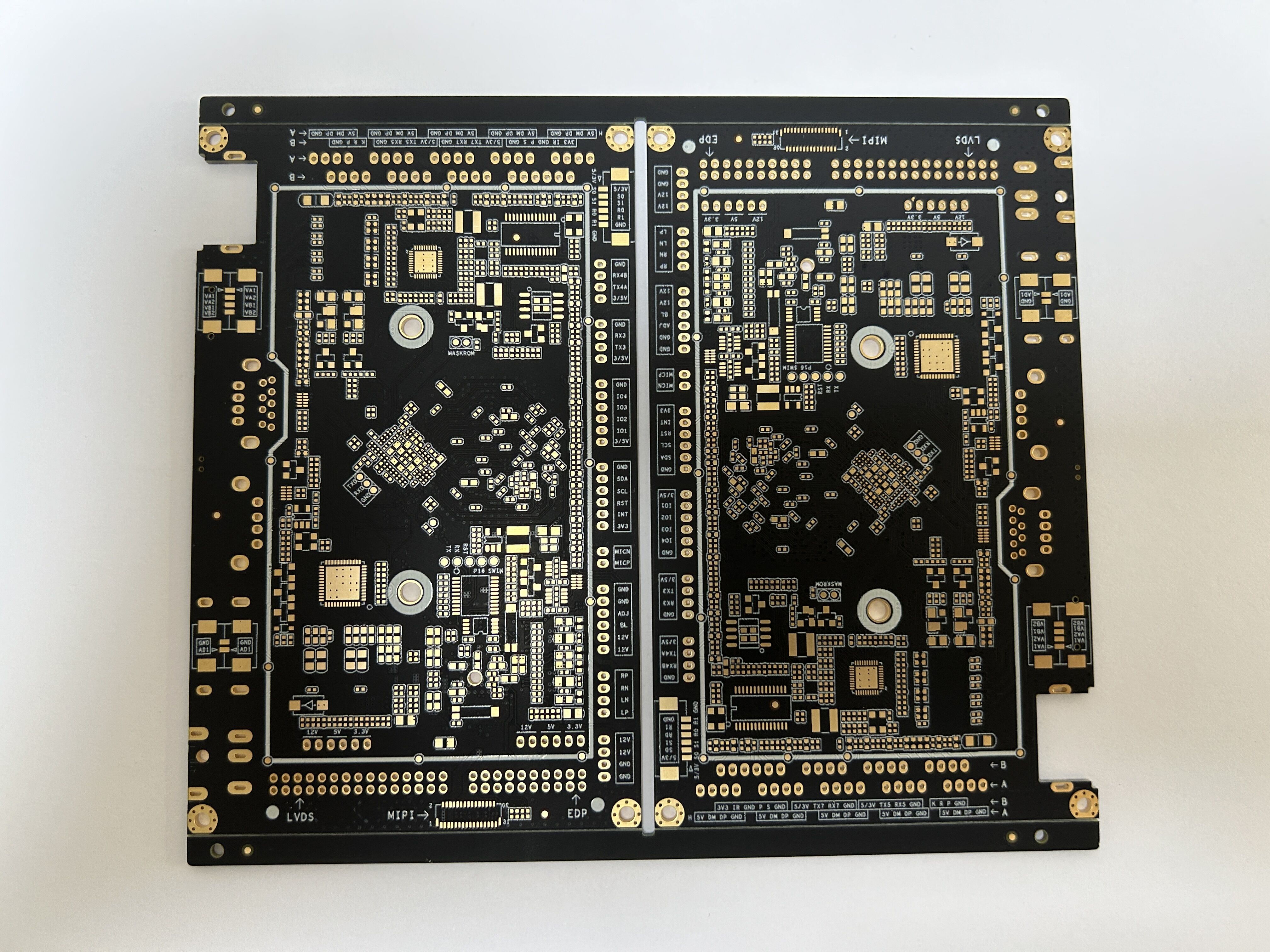

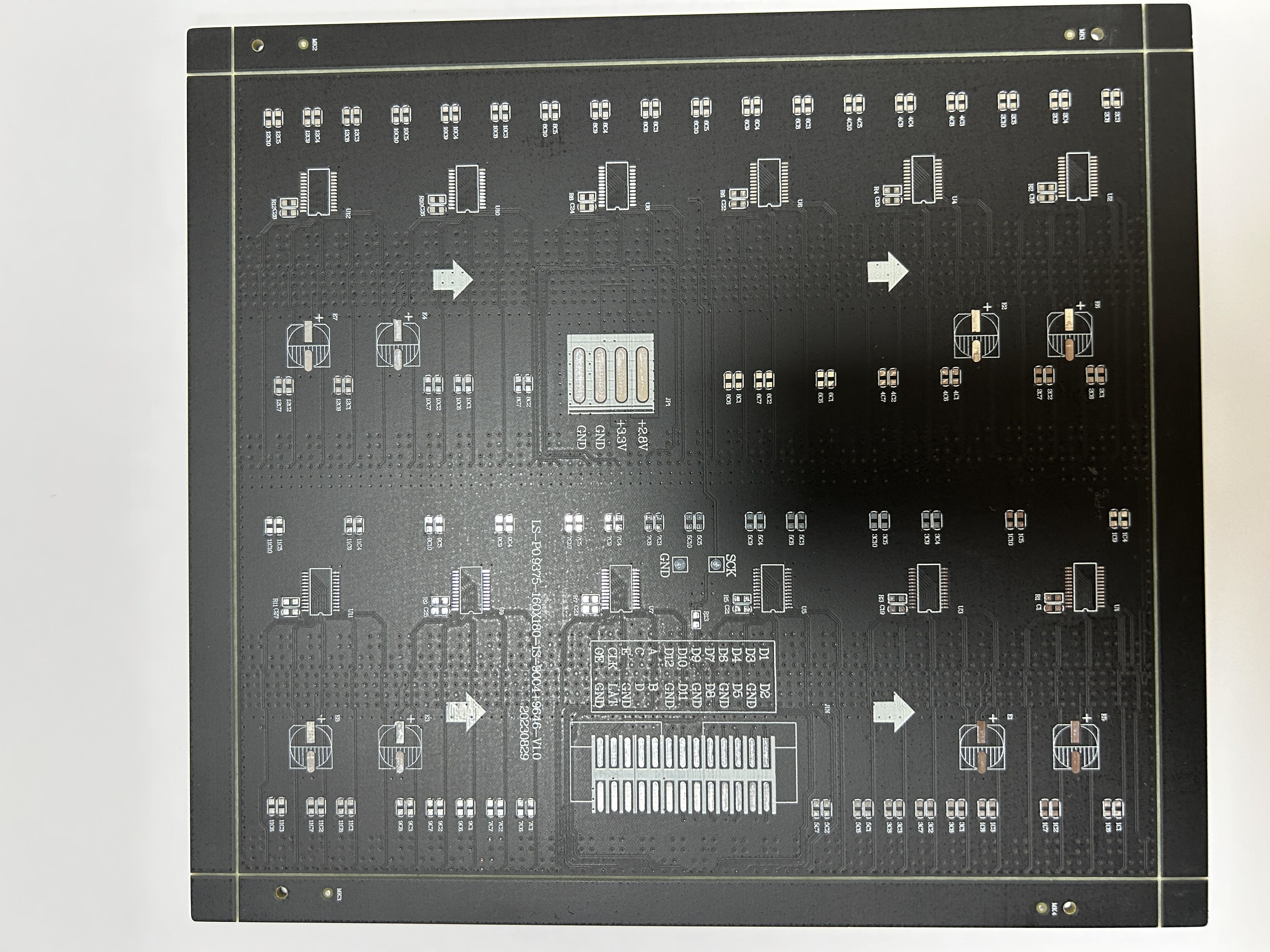

In the ever-evolving world of electronics, custom prototype multi-layer pcbs (Printed Circuit Boards) play a crucial role in developing advanced, high-performance electronic devices. These specialized PCBs offer enhanced functionality, reliability, and miniaturization, making them ideal for cutting-edge technology applications. This article delves into the significance of custom prototype multi-layer PCBs, their benefits, and the key considerations for selecting the right solution for your electronic projects.

What Are Custom Prototype Multi-Layer PCBs?

Custom prototype multi-layer PCBs are specialized circuit boards designed with multiple layers of conductive material separated by insulating layers. This design allows for increased circuit density, improved signal integrity, and reduced electromagnetic interference. Multi-layer PCBs are essential for complex electronic devices requiring high performance and compact design.

Benefits of Custom Prototype Multi-Layer PCBs

1. Enhanced Performance

Multi-layer PCBs offer superior performance by providing more routing options for signals and power. This reduces signal degradation and interference, leading to higher reliability and efficiency in electronic devices. The multiple layers allow for better thermal management and electrical performance, essential for advanced electronics.

2. Compact Design

One of the primary advantages of multi-layer PCBs is their ability to support compact and complex designs. By stacking layers, designers can reduce the board's footprint, making it possible to create smaller and lighter electronic devices without compromising functionality. This compact design is crucial for modern gadgets and portable devices.

3. Improved Signal Integrity

With multiple layers dedicated to signal routing and power distribution, multi-layer PCBs provide enhanced signal integrity. This is particularly important for high-speed digital applications where signal loss and interference can significantly impact performance. The controlled impedance and shielding offered by multi-layer designs ensure stable and accurate signal transmission.

4. Increased Reliability

Custom multi-layer PCBs are designed to meet rigorous reliability standards. The use of high-quality materials and precise manufacturing processes ensures that these boards can withstand harsh environmental conditions, thermal stress, and mechanical strain. This reliability is essential for mission-critical applications in aerospace, medical, and industrial sectors.

Key Considerations for Custom Multi-Layer PCB Prototypes

1. Design Specifications

When creating a custom multi-layer PCB prototype, it is crucial to define the design specifications clearly. This includes the number of layers, layer stack-up, material selection, and routing requirements. Detailed specifications help ensure that the final PCB meets the performance and reliability criteria of your project.

2. Manufacturing Capabilities

Choosing a PCB manufacturer with advanced capabilities and experience in multi-layer PCB production is essential. Ensure that the manufacturer can handle the complexity of your design and provide high-quality prototypes. Look for certifications and a track record of successful multi-layer PCB projects.

3. Testing and Validation

Thorough testing and validation are critical for custom multi-layer PCBs to ensure they perform as expected. Perform electrical testing, signal integrity analysis, and thermal analysis to identify and address any potential issues before final production. This helps prevent costly errors and ensures the prototype meets all functional requirements.

4. Cost and Lead Time

Consider the cost and lead time for producing custom multi-layer PCB prototypes. While advanced designs may come with higher costs, balancing performance requirements with budget constraints is important. Discuss lead times with your manufacturer to ensure that the prototype is delivered within your project timeline.

Applications of Custom Multi-Layer PCBs

1. Consumer Electronics

Custom multi-layer PCBs are widely used in consumer electronics, including smartphones, tablets, and wearables. Their compact design and high performance enable the development of advanced features and functionality in these devices.

2. Medical Devices

In medical technology, multi-layer PCBs are used in diagnostic equipment, patient monitoring systems, and medical imaging devices. Their reliability and precision are critical for ensuring accurate and safe operation in medical applications.

3. Automotive Electronics

The automotive industry relies on multi-layer PCBs for advanced driver assistance systems (ADAS), infotainment systems, and control modules. These PCBs must meet stringent performance and reliability standards to ensure safety and functionality in vehicles.

4. Industrial Equipment

Custom multi-layer PCBs are used in industrial automation, robotics, and control systems. Their ability to handle complex circuitry and harsh environmental conditions makes them ideal for demanding industrial applications.

Conclusion

Custom prototype multi-layer PCBs are essential for developing advanced electronics that require high performance, compact design, and reliable operation. By understanding the benefits and considerations associated with these PCBs, you can make informed decisions for your electronic projects. Whether you are working on consumer electronics, medical devices, automotive systems, or industrial equipment, custom multi-layer PCBs provide tailored solutions to meet your specific needs and drive innovation in technology.