Introduction to Metal Core PCBs

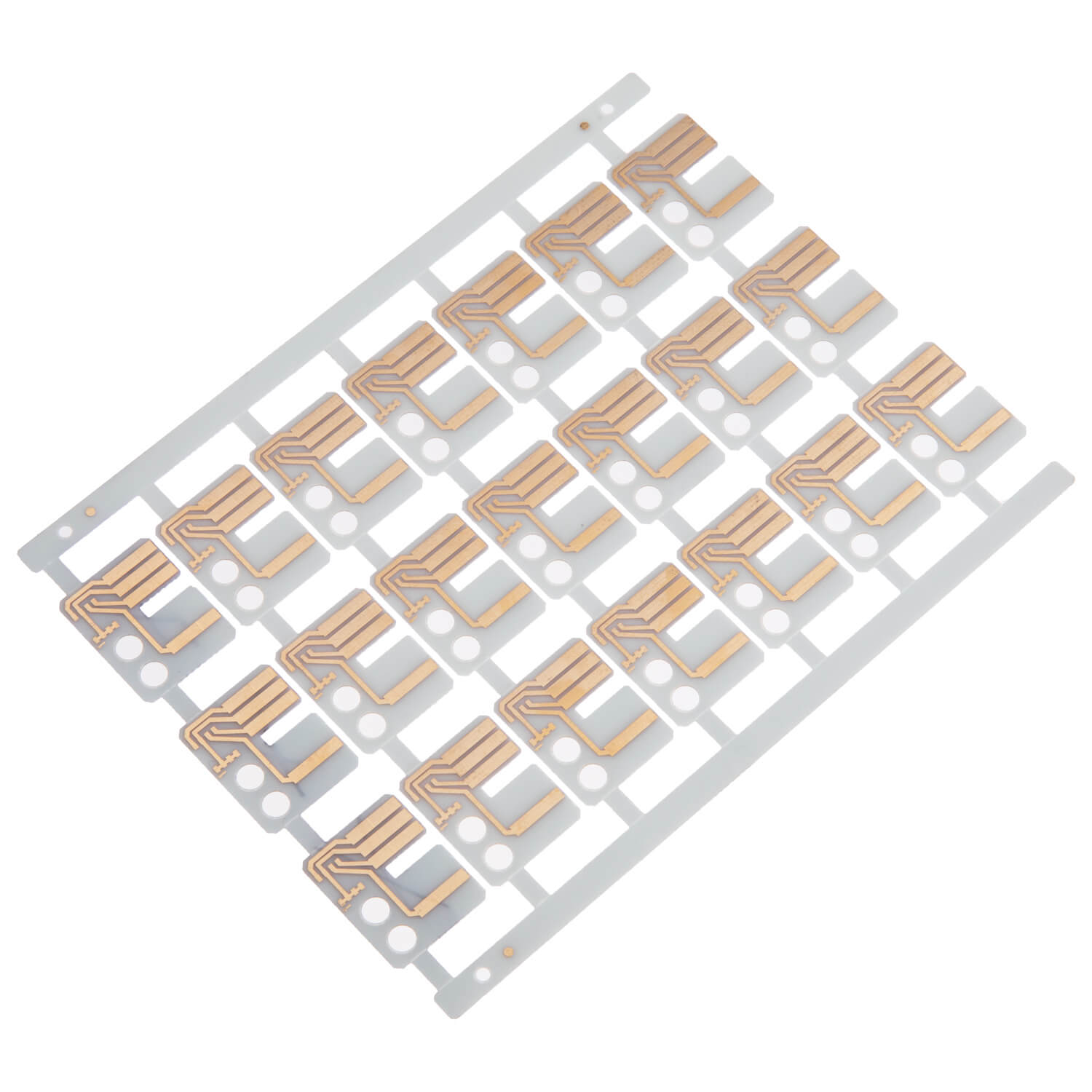

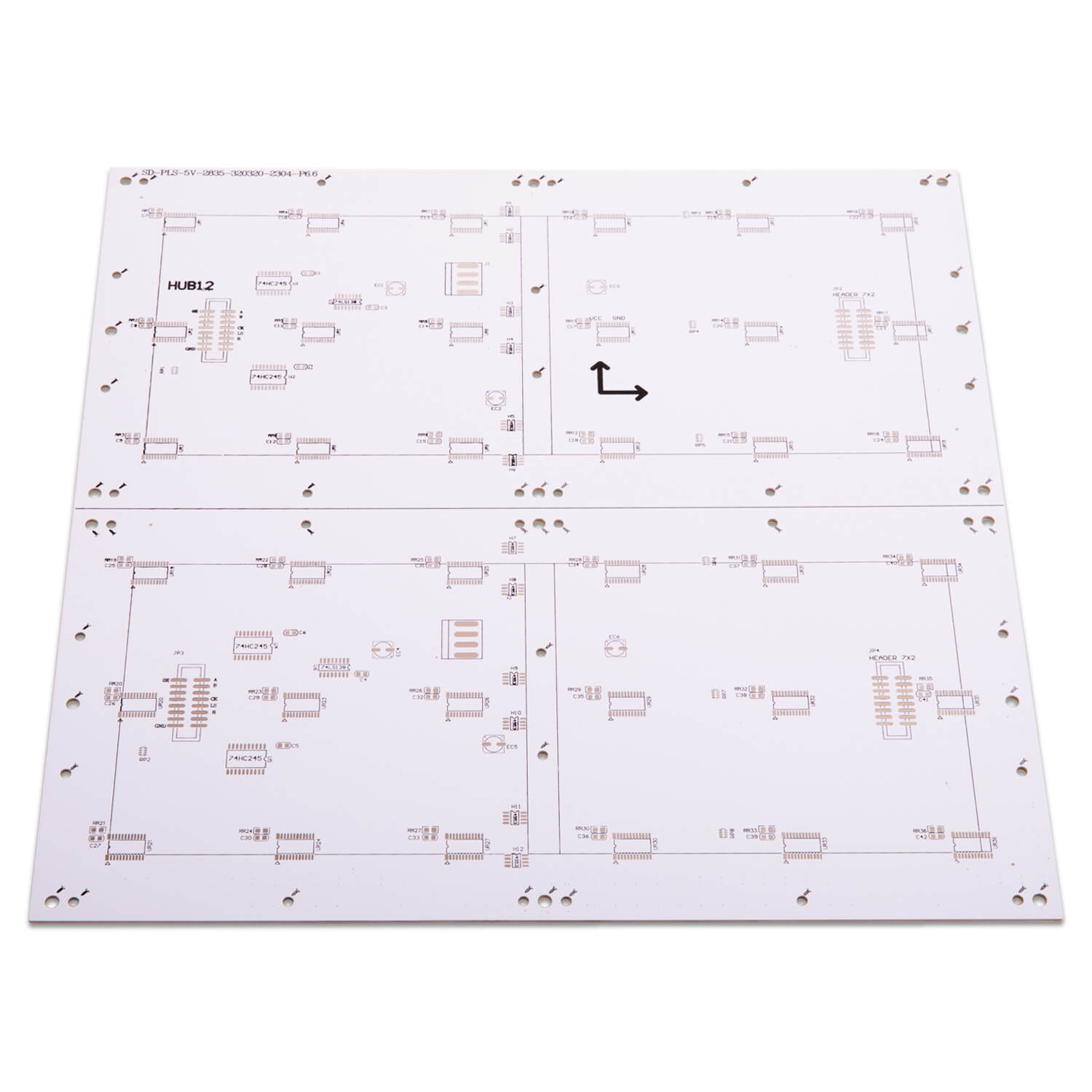

Metal core printed circuit boards (MCPCBs) are a unique and innovative type of circuit board that offer a range of advantages over traditional FR-4 (fiberglass) PCBs. These specialized boards feature a conductive metal layer, typically copper or aluminum, which serves as the core of the board. This core provides enhanced thermal management, improved electrical performance, and increased mechanical strength, making them an attractive choice for a wide variety of applications.

Thermal Management Advantages

One of the primary advantages of MCPCBs is their superior thermal management capabilities. The metal core acts as a highly efficient heat sink, effectively dissipating heat generated by components on the board. This is particularly crucial in high-power applications, such as LED lighting, power electronics, and automotive electronics, where heat buildup can significantly impact the performance and lifespan of the components. By efficiently dissipating heat, MCPCBs help maintain the optimal operating temperature of the components, reducing the risk of thermal-related failures and extending the overall lifetime of the electronic device.

Electrical Performance Enhancements

The conductive nature of the metal core in MCPCBs also offers significant electrical performance benefits. The metal layer provides a low-resistance path for the flow of electrical signals, reducing the impedance and improving signal integrity. This is especially advantageous in high-frequency and high-speed applications, such as RF and microwave circuits, where the metal core helps minimize signal distortion and electromagnetic interference (EMI). Additionally, the metal core can act as a ground plane, further enhancing the electrical characteristics of the PCB and improving the overall circuit performance.

Mechanical Strength and Durability

Another key advantage of MCPCBs is their superior mechanical strength and durability. The metal core provides a robust and rigid structure, making the boards less prone to warping, bending, or deformation compared to traditional FR-4 PCBs. This improved structural integrity is particularly beneficial in applications that experience high levels of vibration, shock, or physical stress, such as industrial equipment, transportation systems, and military/aerospace electronics. The increased durability of MCPCBs helps ensure the reliable operation of the electronic devices even in challenging environments.

Applications of Metal Core PCBs

The unique properties of MCPCBs make them suitable for a wide range of applications across various industries. Some of the most common applications include:

1. Power electronics: MCPCBs are widely used in power converters, motor drives, and high-power LED lighting systems, where their superior thermal management capabilities are crucial for efficient and reliable operation.

2. Automotive electronics: MCPCBs are employed in automotive applications, such as engine control units, power steering systems, and infotainment systems, due to their durability and ability to withstand harsh environmental conditions.

3. Industrial and commercial electronics: MCPCBs find applications in industrial machinery, process control equipment, and commercial HVAC systems, where their thermal management and mechanical strength are highly valued.

4. RF and microwave circuits: The electrical performance advantages of MCPCBs make them a popular choice for high-frequency and high-speed RF and microwave circuits, including radar systems, satellite communications, and 5G infrastructure.

5. Aerospace and defense: MCPCBs are used in aerospace and defense applications, such as avionics, satellite payloads, and military electronics, where their reliability, thermal management, and mechanical integrity are critical factors.

The versatility and advantages of MCPCBs continue to drive their adoption across a diverse range of industries, making them an essential component in the development of advanced electronic systems and devices.

Conclusion

Metal core printed circuit boards offer a compelling solution for a wide range of electronic applications, providing enhanced thermal management, improved electrical performance, and increased mechanical strength. By harnessing the unique properties of conductive metal cores, MCPCBs enable the design and development of more reliable, efficient, and durable electronic systems. As the demand for high-performance and reliable electronics continues to grow, the advantages and applications of metal core PCBs will undoubtedly continue to shape the future of the industry.