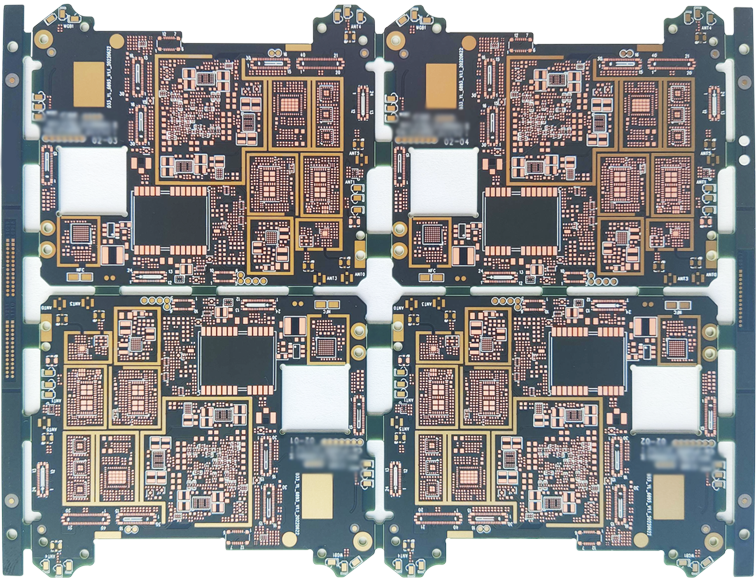

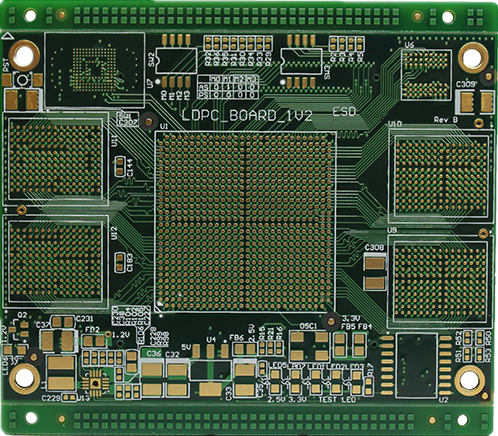

High density interconnect printed circuit boards (HDI PCBs) represent a significant advancement in electronics manufacturing, offering enhanced functionality and versatility for a wide range of applications. These specialized circuit boards are designed to accommodate more components and connections in a smaller footprint, making them ideal for compact electronic devices where space is at a premium.

What are HDI PCBs?

HDI PCBs are characterized by their intricate design and advanced manufacturing techniques. Unlike traditional PCBs, which typically feature two or four layers of conductive material separated by insulating layers (substrates), HDI PCBs incorporate multiple layers of thin conductive material and vias (plated through-holes) to achieve higher connection densities. This allows for greater routing flexibility and more efficient use of space on the board.

Benefits of HDI PCBs

1.Compact Size: HDI PCBs enable the design of smaller and lighter electronic products by reducing the overall size of the circuit board while maintaining or increasing functionality.

2.Improved Electrical Performance: The shorter signal paths and reduced electromagnetic interference (EMI) achieved with HDI PCBs contribute to enhanced electrical performance and reliability.

3.Increased Design Flexibility: With more routing options and tighter spacing between components, designers have greater flexibility to optimize layouts and integrate complex functionality into smaller form factors.

4.Enhanced Reliability: Advanced manufacturing processes and materials used in HDI PCBs contribute to improved durability and longevity, crucial for applications requiring robust performance under varying environmental conditions.

Applications of HDI PCBs

HDI PCBs find extensive use across diverse industries:

Consumer Electronics: Smartphones, tablets, wearables, and other portable devices benefit from HDI PCBs' ability to pack more features into smaller dimensions.

Medical Devices: Compact medical equipment, diagnostic devices, and implantable devices rely on HDI PCBs for high reliability and performance in critical healthcare applications.

Automotive: Advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle components utilize HDI PCBs to meet stringent size, weight, and performance requirements.

Telecommunications: Network routers, switches, and communication devices leverage HDI PCBs to support high-speed data transmission and connectivity.

Innovations in HDI PCB Technology

Recent innovations in HDI PCB technology focus on improving manufacturing processes, increasing layer count capabilities, and integrating advanced materials to meet evolving industry demands. Techniques such as laser drilling, sequential lamination, and microvia filling contribute to achieving finer features and tighter design tolerances in HDI PCBs.

Conclusion

High Density Interconnect Printed Circuit Boards (HDI PCBs) represent a cornerstone of modern electronics manufacturing, enabling smaller, more efficient, and reliable electronic devices across various industries. As technology continues to advance, the demand for HDI PCBs will likely grow, driven by their ability to deliver superior performance in compact form factors. By understanding their benefits, applications, and ongoing innovations, manufacturers and designers can harness the full potential of HDI PCBs to drive innovation and meet the challenges of tomorrow's electronic designs.