The Key Components of Multilayer PCBs

Multilayer PCBs (printed circuit boards) are essential components of modern electronic devices, providing a platform for interconnecting various electronic components. These complex boards consist of multiple layers of different materials and require careful construction. This article aims to explore the commonly used materials in the construction of multilayer PCBs and their significance.

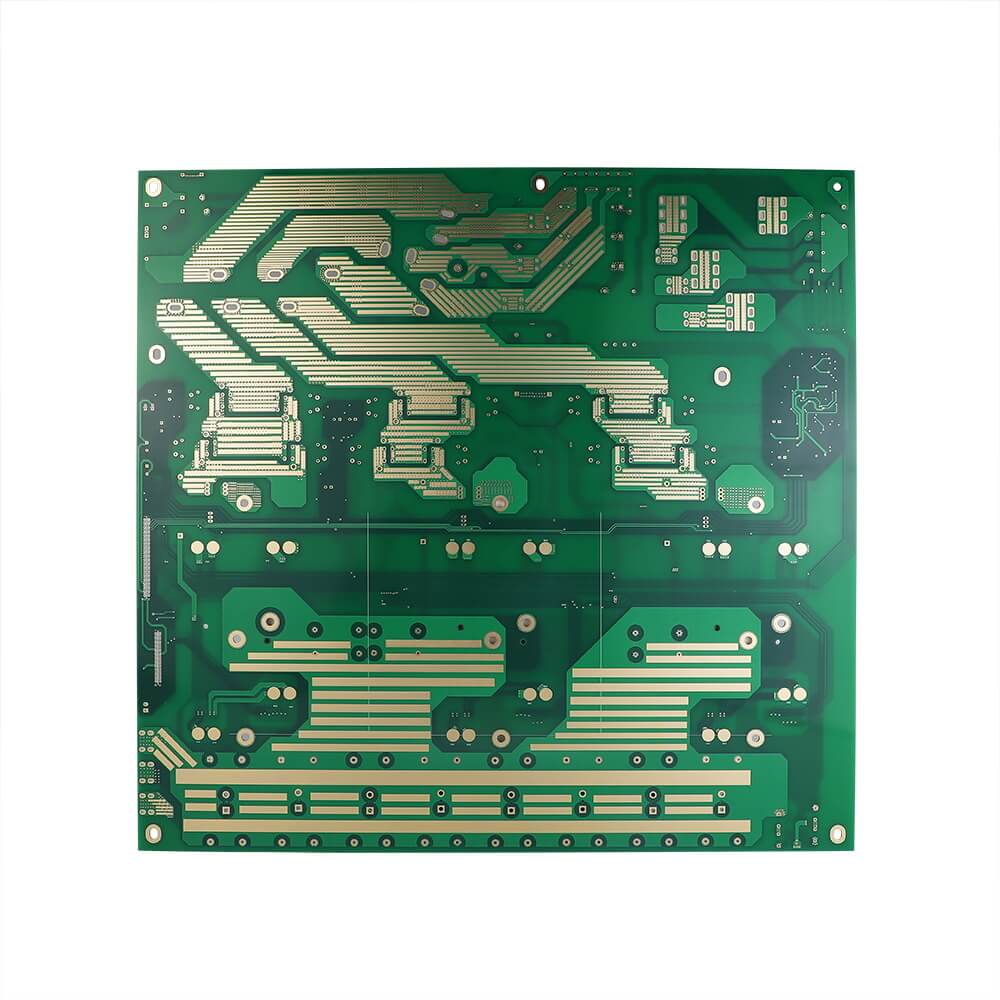

The Substrate Material: FR-4

The substrate material, also known as the core, is one of the most critical components of multilayer PCBs. FR-4 (Flame Retardant 4) is the most widely used substrate material due to its excellent electrical insulation properties, mechanical strength, and cost-effectiveness. It is a type of glass-reinforced epoxy laminate that can withstand high temperatures and offers excellent dimensional stability.

Copper Foil: The Conductive Backbone

Copper foil is used as the conductive layer in multilayer PCBs, providing the necessary electrical connectivity. The foil is typically laminated to both sides of the FR-4 substrate material, allowing for the creation of conductive pathways. Copper is chosen for its high electrical conductivity and good adhesion properties with the substrate material. The thickness of the copper foil is carefully selected based on the specific application requirements.

Prepreg: The Insulating Layer

Prepreg, short for pre-impregnated, is a thin layer of fiberglass cloth impregnated with resin. It serves as the insulation layer between the different copper layers in a multilayer PCB. Prepreg is selected based on various factors such as resin content, resin type, and thickness. The use of prepreg ensures adequate isolation between different signal layers and helps maintain signal integrity.

Soldermask: Protecting and Identifying Layers

Soldermask is a protective layer applied to the surface of a multilayer PCB. It is typically made of epoxy resin mixed with a pigment to provide color. The soldermask serves multiple purposes: it protects the copper traces from environmental factors, prevents solder bridges during assembly, and assists in the identification of different layers. Common colors for soldermask include green, red, blue, and black.

Silkscreen: Component Identification and Placement

The silkscreen layer is used to print component markings and symbols on the surface of a multilayer PCB. It provides valuable information to assembly technicians, aiding in the correct placement of components and debugging processes. The silkscreen layer is typically printed in white, but other colors may be used. It also adds an aesthetic appeal to the final product.

Summary

The construction of multilayer PCBs involves a combination of several materials. The substrate material, typically FR-4, provides mechanical support and insulation. Copper foil serves as the conductive layer, while prepreg ensures proper insulation between different signal layers. Soldermask protects the circuitry and aids in layer identification, and the silkscreen layer provides component markings and instructions. The selection of these materials is crucial to ensure the performance, reliability, and cost-effectiveness of multilayer PCBs in various electronic devices.