In the dynamic world of electronics, Printed Circuit Boards (PCBs) stand as the backbone, enabling the seamless integration of various electronic components. Among the myriad types of PCBs, the double-sided PCB emerges as a versatile solution, revolutionizing the landscape of electronic design and manufacturing.

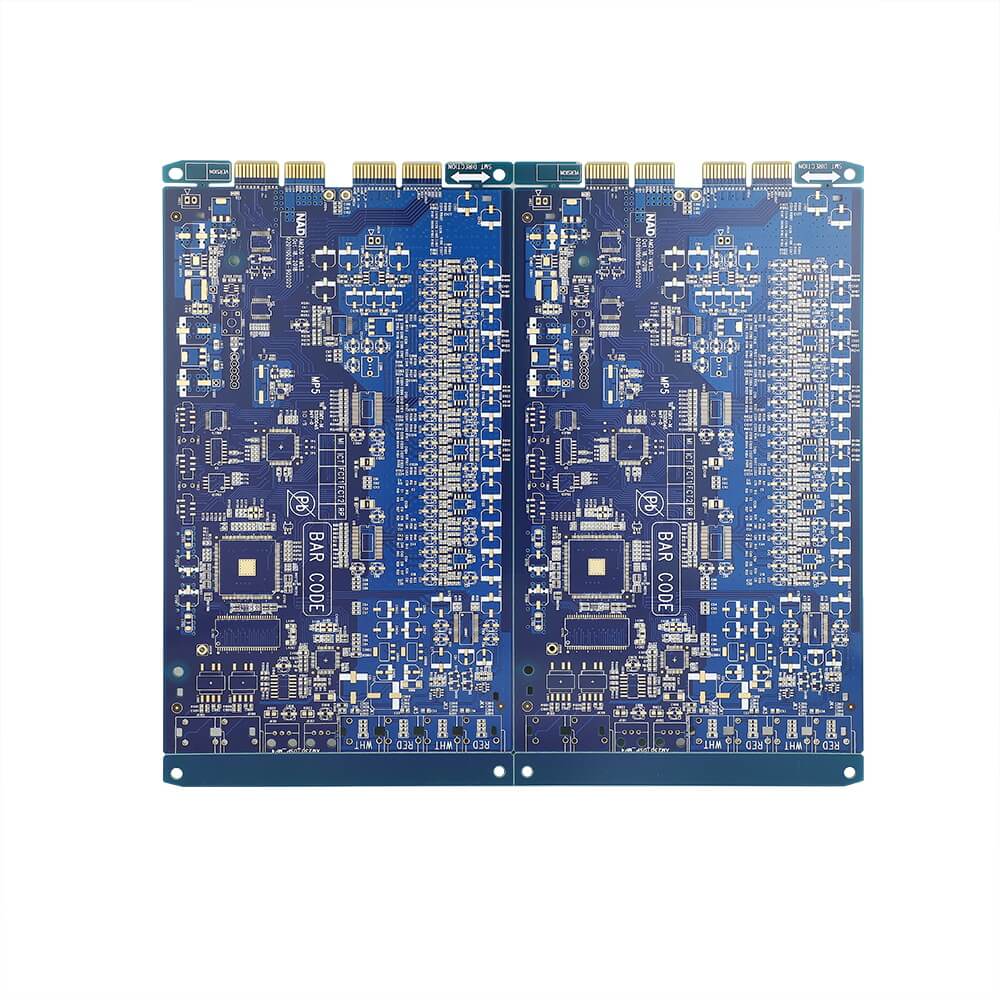

A double-sided PCB, as the name suggests, features conductive layers on both sides of the board, enhancing its functionality and flexibility compared to its single-sided counterpart. This innovative design allows for the accommodation of more complex circuitry within a compact space, making it an indispensable choice for a wide array of applications across industries.

One of the primary advantages of double-sided PCBs lies in their enhanced circuit density. By utilizing both sides of the board for component placement and interconnections, designers can optimize space utilization without compromising on functionality. This makes double-sided PCBs ideal for devices where space constraints are paramount, such as smartphones, medical devices, and automotive electronics.

Moreover, the versatility of double-sided PCBs extends beyond mere spatial efficiency. These boards facilitate the implementation of more intricate circuit designs, incorporating advanced functionalities and features. Whether it's intricate signal routing, impedance matching, or power distribution, double-sided PCBs offer the flexibility to accommodate diverse design requirements, catering to the evolving needs of modern electronics.

In the realm of professional PCB manufacturing, the production of double-sided PCBs demands precision and expertise. Professional PCB manufacturers leverage cutting-edge technologies and meticulous processes to ensure the highest quality and reliability of the final product. From precise drilling and etching to meticulous soldering and assembly, every step in the manufacturing process is executed with utmost precision to meet the stringent standards of the industry.

The applications of double-sided PCBs span across a multitude of industries, ranging from consumer electronics to industrial automation and beyond. In consumer electronics, these boards find application in smartphones, tablets, and wearable devices, where compact size and high functionality are paramount. In automotive electronics, double-sided PCBs power a myriad of systems, including engine control units, infotainment systems, and advanced driver assistance systems (ADAS).

Furthermore, double-sided PCBs play a crucial role in industrial automation, facilitating the control and monitoring of complex machinery and processes. From factory automation to renewable energy systems, these boards enable seamless integration and efficient operation, driving innovation and productivity across industries.

In conclusion, double-sided PCBs represent a cornerstone of modern electronic design and manufacturing, offering unparalleled versatility, functionality, and reliability. As technology continues to advance, the demand for double-sided PCBs is poised to soar, driving the need for professional PCB manufacturers to deliver innovative solutions that meet the evolving needs of the industry. With their expertise and commitment to excellence, professional PCB manufacturers stand as the cornerstone of the double-sided PCB revolution, shaping the future of electronics one circuit at a time.